COMPUTER INTEGRATED MANUFACTURING LAB

CORE EQUIPMENTS

| CNC Lathe Machine |

ACE Micromatic FANUC Controlled SimpleTurn 5075 CNC Lathe by ACE Micromatic |

| CNC Engraving Machine |

Shilpin SIEMENS 808D Controlled Engraving/Micro-Milling Machine (SE 4454-S), by Logical Automation Pvt. Ltd. |

| CNC Trainer Rack |

SIEMENS 828D Controlled CNC Trainer Rack by Christiani, Germany |

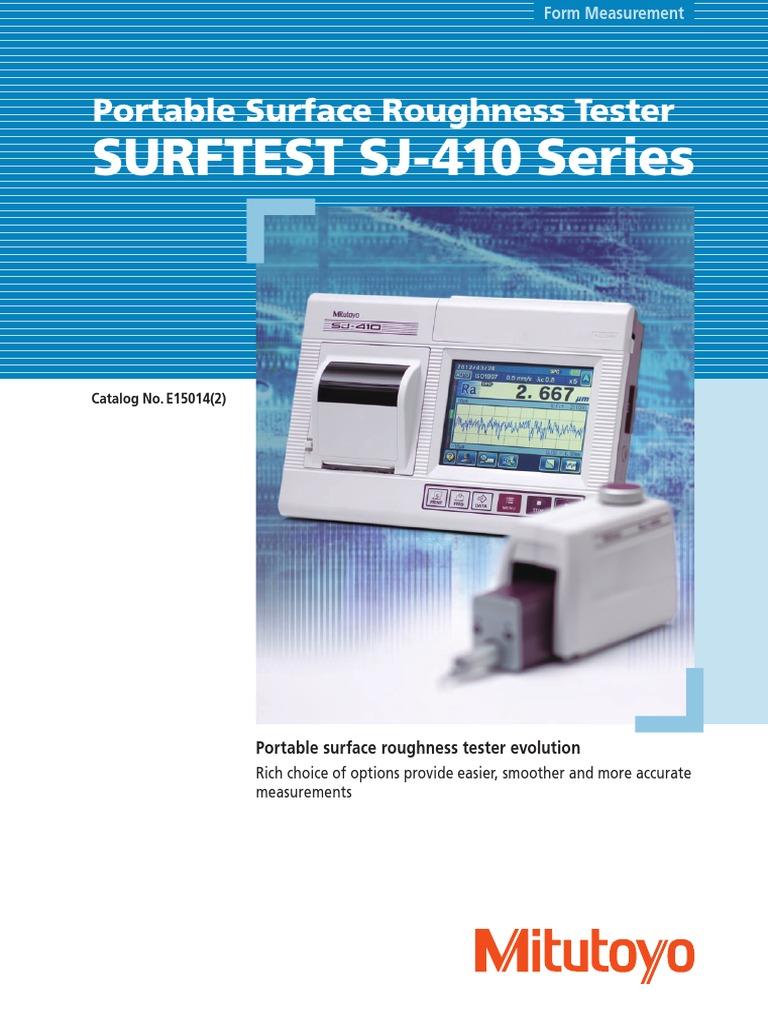

| Surface Roughness Tester |

Mitutoyo SurfTest Sj-410, by Mitutoyo Asia |

| CAD/CAM Solutions |

1. Siemens SinuTrain Software for CNC Lathe and Milling Programming and Simulations by Christiani, Germany

2. MSC Software by USA |

ACE Micromatic SimpleTurn 5075 CNC Lathe Machine

Simple turn series are flatbed 2-axes horizontal CNC turning centres designed to bridge the gap between manual & CNC turning lathes. The electronic hand wheels on these machines are thoughtfully placed imparting flexibility. Simpleturn machines are ideal for tool room applications, small batch productions & people wanting to switch from a manual lathe to CNC.

LEARNING TARGETS:

- Job Planning:- Work Safety, Materials, Tools, Work Holders

- Basics of CNC Technology:- Reading Drawings, History & Structure of CNC Machines, Coordinate System, Tool Movement, Preparatory Functions,

- Programming:- SINUMERIK Operator Interface, Programming for Turning & Milling, Programming Example, Tool Measurement/Management

- Machining at the Machine: - Working Safety at the Machine, Checking the Oil/Coolant Level, Setting up the machine, machining a Workpiece.

- Quality Assurance: - Simple Measurements using Mitutoyo SurfTest SJ-410 Surface Roughness Tester.

TECHNICAL DATA:

| Brand |

Ace Micromatic |

| Model Number |

Simpleturn 5075 |

| Maximum Turning Length |

620 mm |

| Spindle Size |

A2-6 |

| Spindle Motor Power Fanuc Continuous |

7.5 kW |

| Swing Over Bed |

500 mm |

| Swing Over Carriage |

280 mm |

| Distance Between Centers |

750 mm |

| Turret Type |

4 station vertical axis |

| No Of Stations |

4 |

| Max Boring Bar Dia |

32mm |

| Od Turning Tool Size |

25x25 mm |

| Tailstock Base Travel |

180 mm |

| Tailstock Quill Dia |

80mm |

| Tailstock Quill Taper |

MT-5 |

| Coolant Tank Capacity |

110 l (litre) |

| Overall Dimensions L x w x h |

2500 x2000 x 1900 mm |

| Overall Weight |

~1800 Kg |

CNC ENGRAVING MACHINE

SHILPIN ENGRAVING MACHINE SE 4454-S (SIEMENS 808D CNC Controller)

- 3-Axes Double Column Machine

- High Precision Ball Screws and Linear Guideways

- Siemens Make 808D CNC Controller

- Servo Drives & Motors for axes with absolute encoder

- High Precision integrated electro spindle

- Standard ISO G-Code Language

LEARNING TARGETS:

- Job Planning:- Work Safety, Materials, Tools, Work Holders

- Basics of CNC Technology:- Reading Drawings, Coordinate System, Tool Movement,

- Programming:- SINUMERIK Operator Interface, Programming for Milling/Engraving, Programming Example, Tool Measurement/Management

- Machining at the Machine: - Working Safety at the Machine, Checking the Oil/Coolant Level, Setting up the machine, machining a Workpiece.

- Quality Assurance: - Simple Measurements using Mitutoyo SurfTest SJ-410 Surface

TECHNICAL DATA:

| Model |

SE4454-S |

| Table Size X Y (mm) |

440 X 540 |

| Machine Area (mm) |

410 X 410 X 150 |

| XYZ Axis Travel (mm) |

420 X 420 X 200 |

| Accuracy X Y Z (mm) |

< 0.02 |

| Repeatability X Y Z (mm) |

< 0.01 |

| Table Flatness (mm) |

< 0.03 |

| Spindle Power (KW) |

3.6 |

| Spindle Speed (RPM) Max |

24,000 |

| Max. Tool Size (mm) |

10 |

| Rapid Rate (m/min) |

10 |

| Feed Rate (m/min) |

2 |

| Net Weight (Kg) |

110 |

CNC TRAINER RACK

CNC Trainer Rack (SIEMENS 828D CNC Controller)

Open form CNC where students can learn how to build a CNC. Having 828D CNC Controller where we/students can program, simulate the part programs and check for any corrections/changes; and only after it students will perform the actual machining on other SIEMENS Controlled Machine. So, by using CNC Trainer Rack, students will experience the machining operation.

LEARNING TARGETS:

Programming:- SINUMERIK Operator Interface, Programming for Turning & Milling, Programming Example

TECHNICAL DATA:

| Brand |

Christiani, Germany |

| Controller |

SIEMENS 828D CNC Controller |

SURFACE ROUGHNESS TESTER

MITUTOYO SURFTEST SJ- 410 Surface Roughness Tester

- Skidded measurement is possible with this series. Equipped with 46 roughness parameters that conform to the latest ISO, DIN, ANSI, and JIS standards.

- Measuring range: 800μm

- Resolution: 0.000125μm (at 8μm range)

- The handheld data processing unit and the 5.7-inch color graphic LCD touch-panel provides superior readability and operability. The LCD also includes a backlight for improved visibility in dark environments.

- Auto-calibration function

LEARNING TARGETS:

- Quality Assurance: - Simple Measurements using Mitutoyo SurfTest SJ-410 Surface Roughness Tester.

TECHNICAL DATA:

| Brand |

Mitutoyo |

| Model Number |

SurfTest SJ-410 |

| Measuring Range |

25 mm (1 Inch) |

| Measuring Principle |

Differential Inductance |

| Detector Measuring Force |

0.75 mN |

| Standards |

JIS1982 / JIS 1994/ JIS 2001/ ISO 1997/ ANSI/ VDA |

| Cut-Off Length (mm) |

0.08, 0.25, 0.8, 2.5, 8 |

| Mass (Total) |

2.7 Kg(With All Standard Accessories) |

SIEMENS SINUTRAIN SOFTWARE

SIEMENS SINUTRAIN SOFTWARE From Christiani, Germany

- CNC programming on the PC as on the CNC - same operation and programming

- Work preparation even while the machine is still cutting: test, run in and simulate NC programs on the PC - less time-stress at the machine

- CNC training and education with exactly the same programming and user interface as in the workshop - without waiting for "finally getting to it", without the danger of breaking something - and with the possibility of preparing and finishing work at home or on the road.

The advantage for workshop operators: More cutting time, fewer risks!

With SinuTrain, one PC is sufficient for part programming, NC program testing, CNC training and employee training. The machine can meanwhile process parts. And each collision risk detected and eliminated in the SinuTrain simulation prevents damage.

LEARNING TARGETS:

- Programming:- SINUMERIK Operator Interface, Programming for Milling/Engraving, Programming Example, Tool Measurement/Management

TECHNICAL DATA:

| Brand |

SIEMENS |

| Model |

SinuTrain for SINUMERIK OPERATE (4.8) |

MSC Software

MSC SOFTWARE, USA from SSIGMA

MSC Software develops simulation software technology that enables engineers to validate and optimize their designs using virtual prototypes. Customers in almost every part of manufacturing use our software to complement, and in some cases even replace the physical prototype “build and test” process that has traditionally been used in product design.

LEARNING TARGETS:

Students Can Learn linear and nonlinear finite element analysis (FEA), acoustics, fluid-structure interaction (FSI), multi-physics, optimization, fatigue and durability, multi-body dynamics, and control systems simulation.